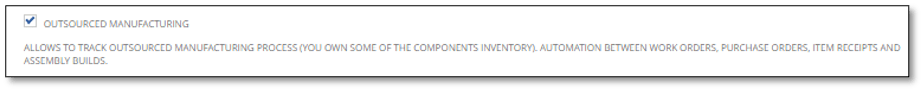

The NetSuite Outsourced Manufacturing feature provides companies with better management for the production of their assemblies that were processed by their outside vendors. With this feature, both purchasing, consumption, and production processes are recorded in NetSuite which allows better visibility to their production process.

Here are the steps required to setup the Outsourced Manufacturing Feature in NetSuite:

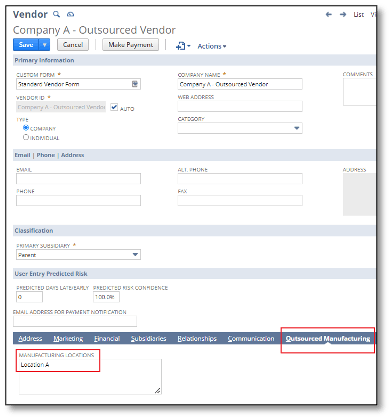

Upon enabling the Outsourced Manufacturing feature, user needs to associate their Outsourced Location to their Vendor records.

If user is unable to see the Outsourced Manufacturing tab, the preferred Vendor form will need to be customized to add this tab.

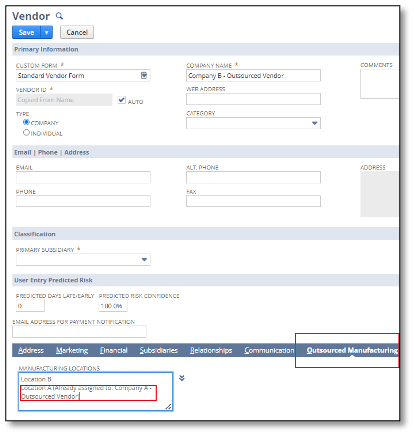

Also, an Outsourced Location can only be associated to one Vendor record but a Vendor record can have multiple associated Outsourced Locations. When adding an Outsourced Location that is already associated to another Outsourced Vendor, there will be a note indicating such information and user will also be prevented from saving the Vendor Record:

User will need to create an Outsourcing Item which serve as the charge or rate imposed by Outsourced Vendors to produce one (1) unit of an outsourced assembly item.

In the Components tab, add the Outsourcing Charge Item created in #3 above. NetSuite will automatically set the quantity for the Outsourcing Charge Item to one (1) quantity. The quantity for the Outsourcing Charge Item is not editable.

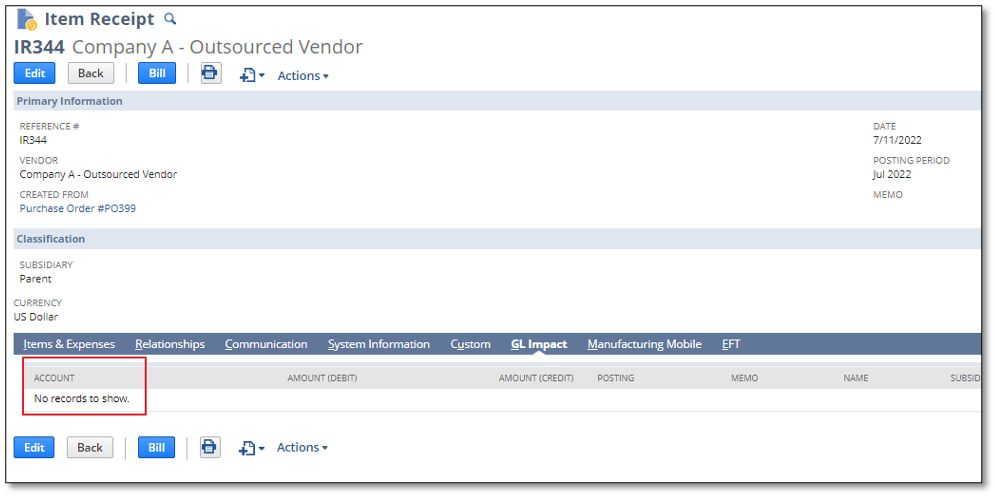

Upon saving the Item Receipt record, a corresponding Assembly Build transaction will be created for the related Work Order. Note that in the Item Receipt record, no GL impact is expected as the GL impact related to the increase of the Assembly, decrease in components, and recording of outsourcing charge, will all be recorded in the Assembly Build record.

As a highly accredited NetSuite Solution Provider, ScaleNorth is well positioned to help you with the full scope of your NetSuite customization needs. If you require more NetSuite assistance, contact ScaleNorth today.